The Advantages of Using a Laser Cleaning Machine for Rust Removal on Cars

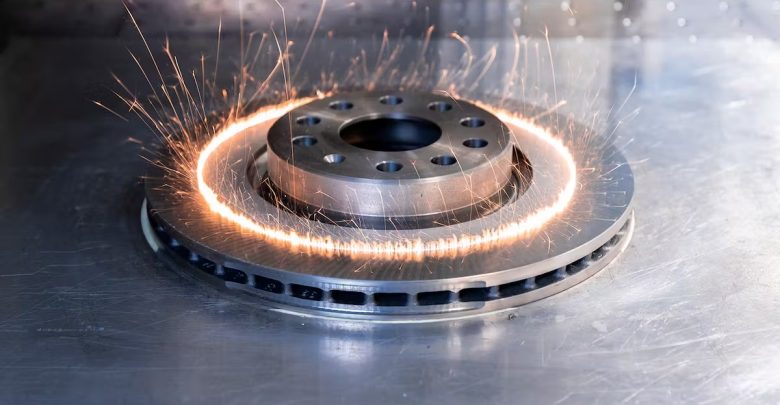

When it comes to tackling the persistent issue of rust on cars, the use of cutting-edge technology has revolutionized traditional methods. Laser rust removal, an advanced technique gaining popularity in the automotive industry, provides a highly efficient and precise solution to combat rust-related challenges.

Laser Rust Removal: A Technological Breakthrough

The advent of laser technology has ushered in a new era for rust removal, making the process more efficient and environmentally friendly. Laser rust removal utilizes focused laser beams to eliminate rust, paint, and contaminants from surfaces without causing damage to the underlying material. This innovative method not only ensures a thorough cleaning but also minimizes the need for harsh chemicals and abrasive techniques.

One of the key advantages of laser rust removal is its precision. The laser can be controlled with remarkable accuracy, allowing for selective removal of rust while preserving the integrity of the unaffected surfaces. This precision is particularly crucial when working on delicate car parts, as it ensures that only the rust is targeted, leaving the rest of the vehicle unharmed.

Furthermore, laser rust removal is a non-contact process, reducing the risk of mechanical damage to the car’s surface. Traditional methods, such as sandblasting or chemical treatments, can sometimes lead to surface abrasions or corrosion. In contrast, the laser approach offers a gentler alternative, making it ideal for preserving the aesthetic appeal of the vehicle.

Efficiency and Time-Saving Benefits

Time is of the essence when it comes to rust removal, especially in the automotive industry. Laser cleaning machines excel in efficiency, significantly reducing the time required for the restoration process. The concentrated laser beams swiftly remove rust, making it a quick and effective solution for both small-scale and large-scale rust problems on cars.

In addition to speed, laser rust removal minimizes the need for manual labor. Traditional methods often involve intensive manual effort, exposing workers to potentially hazardous materials. Laser technology automates the rust removal process, enhancing worker safety and allowing skilled professionals to focus on other critical aspects of automotive restoration.

Versatility and Adaptability: The Handheld Laser Welder

In the middle of the rust removal process, a noteworthy companion emerges – the handheld laser welder. This versatile tool extends the capabilities of laser technology, allowing technicians to address intricate rust spots with precision. The handheld laser welder enables professionals to access hard-to-reach areas, ensuring a comprehensive rust removal process for every nook and cranny of the car.

The handheld nature of this device provides an added layer of flexibility, making it an indispensable tool for automotive restoration. Whether working on a classic car with intricate designs or a modern vehicle with complex geometries, the handheld laser welder complements the main laser cleaning machine, ensuring a thorough and meticulous rust removal process.

Sealing the Deal with Laser Marking

As we approach the end of the rust removal journey, another aspect of laser technology comes into play – the laser marking machine. After successfully eliminating rust, marking and labeling become essential for quality control and traceability. The laser marking machine allows for precise engraving of codes, dates, and other identification marks on the car’s surface, ensuring that each vehicle undergoes a comprehensive restoration process.

Conclusion

In conclusion, the advantages of using a laser cleaning machine for rust removal on cars are evident in its precision, efficiency, and versatility. The integration of a handheld laser welder enhances the adaptability of the technology, while the application of a laser marking machine ensures a holistic approach to automotive restoration. Embracing laser technology in rust removal not only meets the high standards of the automotive industry but also paves the way for a more sustainable and advanced approach to preserving the beauty and functionality of our vehicles.